Building Regulations Fire Safety Approved Document B has been revised and has a direct impact on ventilation systems. Paul Williams, Domus Ventilation Product Manager, explains the new regulations and what you need to do to comply.

For those working in the ventilation sector, Part F is the go-to section of Building Regulations that you will be all too familiar with; it provides guidance on building ventilation, including building air quality and preventing condensation.

However, it’s not the only relevant part of Building Regulations: Building Regulations Fire Safety Approved Document B should be a vital piece in your jigsaw when it comes to understanding, designing and installing a ventilation system in a domestic property. Under Document B, where holes are made in a compartment wall for plastic ventilation ducting to pass through, those walls need to be fire-stopped to restore the walls’ fire rating. There are a range of methods to achieve this, but dedicated products made from intumescent material are by far the best option and the easiest to install. Domus, for example, offers a full range of Fire Sleeves and Fire Collars tested to BSEN 1366-3: 2009.

Post Grenfell, Building Regulations came under close scrutiny, looking at all aspects of fire safety, including ventilation products and systems. Now, Fire Safety Approved Document B has been revised with one specific important change for those in ventilation that came into force in November 2020: “Ductwork penetrating through the external cavity including termination to be non-combustible” when above 18m in England and 11m in Scotland.

What does this mean in practice? It means using air bricks made of plastic is no longer an option above those heights.

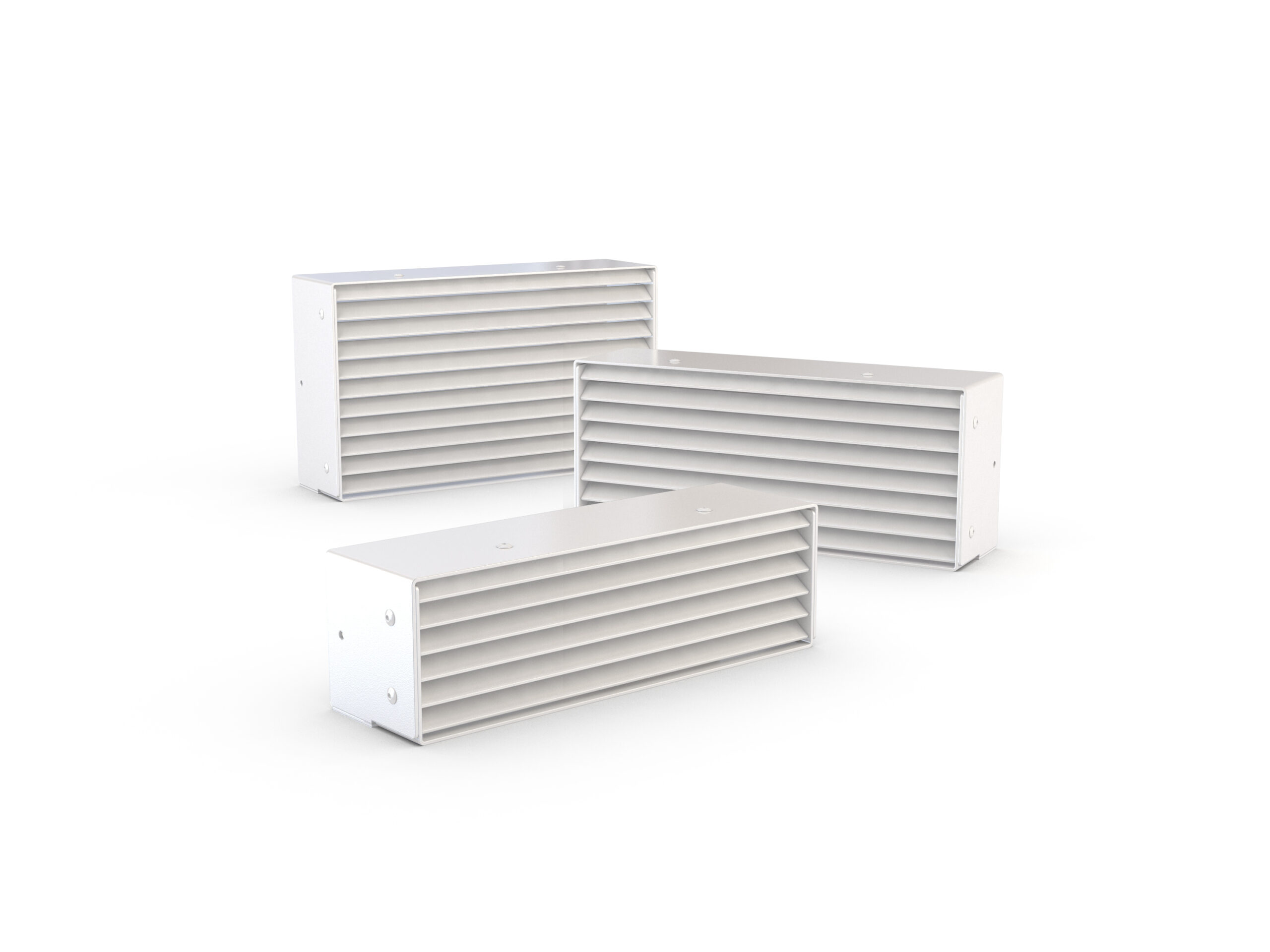

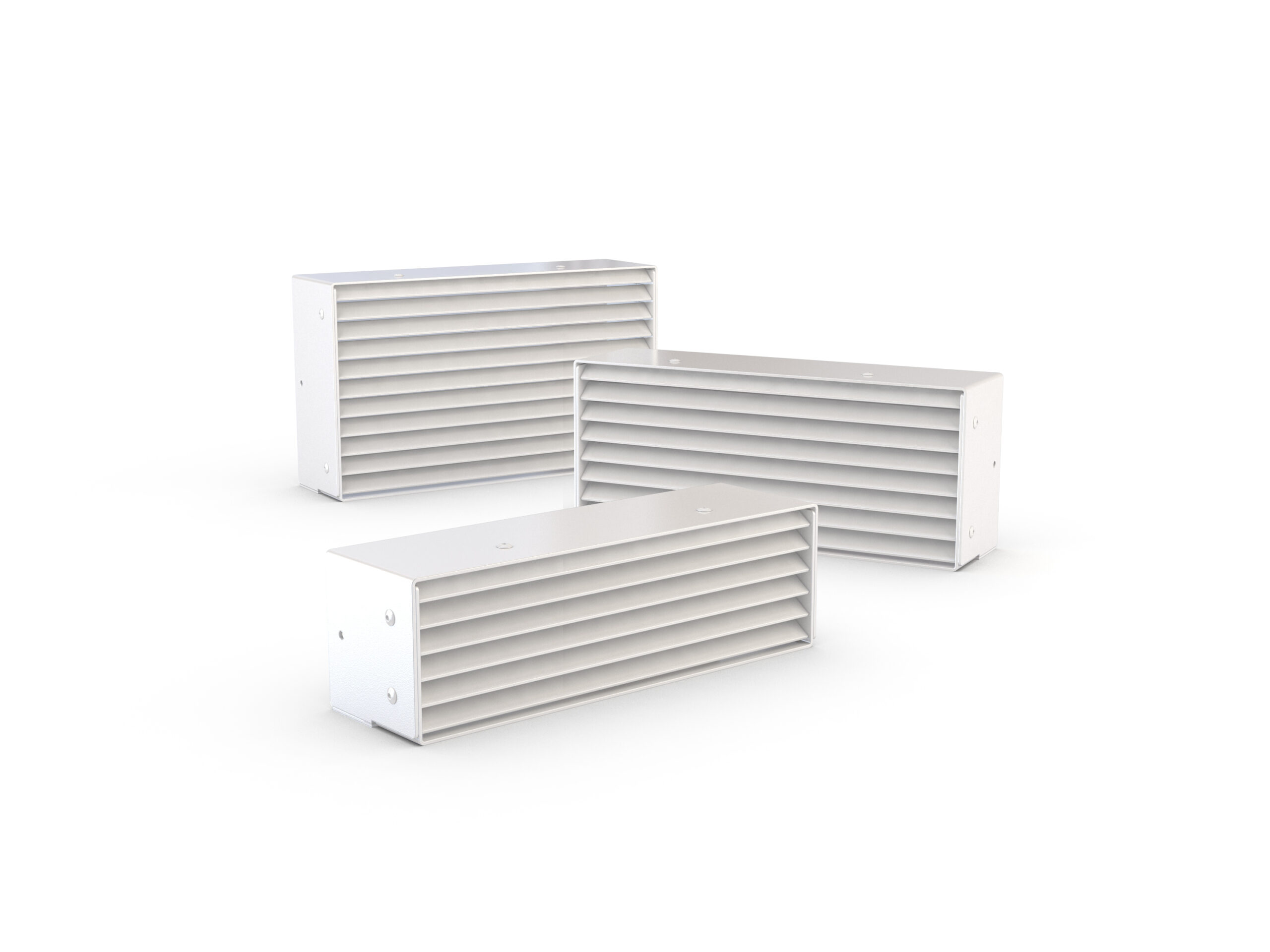

An air brick is a basic, but important part of a building’s ventilation, as it allows fresh air to enter the property, helping to keep it cooler and reducing humidity which can lead to condensation and mould. Air bricks can be used passively, i.e. in a standalone capacity, or with a mechanical ventilation system where they are connected to ducting to assist the air flow both in and out of the premises.

Most air bricks are made from plastic, but plastic is combustible and can contribute to a fire. The compliant alternative is to use an air brick made from non-combustible metal. We have introduced the Solis Air Brick™ range of low resistance, non-combustible metal air bricks that are fully compliant with the revised Building Regulations Fire Safety Approved Document B. They are made from 1.5mm galvanized steel (fire class A1) non-combustible material are suitable for use with all external wall types.

In England, you can continue to use plastic air bricks below the 18m mark, but we would urge you to think twice before doing this and consider the safety of the inhabitants as the number one priority. Furthermore, we expect the more stringent 11m rule that applies in Scotland will eventually be applied throughout the UK, which we see as a positive step. After all, a good ventilation system should improve quality of life, not endanger it.